An example of a pressure vessel is ____. – An example of a pressure vessel is a boiler, which is a closed vessel that contains a fluid under pressure. Boilers are used to generate steam for various industrial and domestic applications, such as power generation, heating, and cooking. The design and construction of boilers must adhere to strict safety standards to ensure their safe operation.

Pressure vessels like boilers play a crucial role in various industries, and their design and maintenance require specialized knowledge and expertise. This article delves into the intricacies of pressure vessel design, manufacturing, and applications, providing valuable insights into these critical components.

Types of Pressure Vessels: An Example Of A Pressure Vessel Is ____.

Pressure vessels are enclosed containers designed to withstand internal pressure. They find applications in various industries, including chemical processing, power generation, and aerospace. Based on their design and intended use, pressure vessels can be categorized into different types:

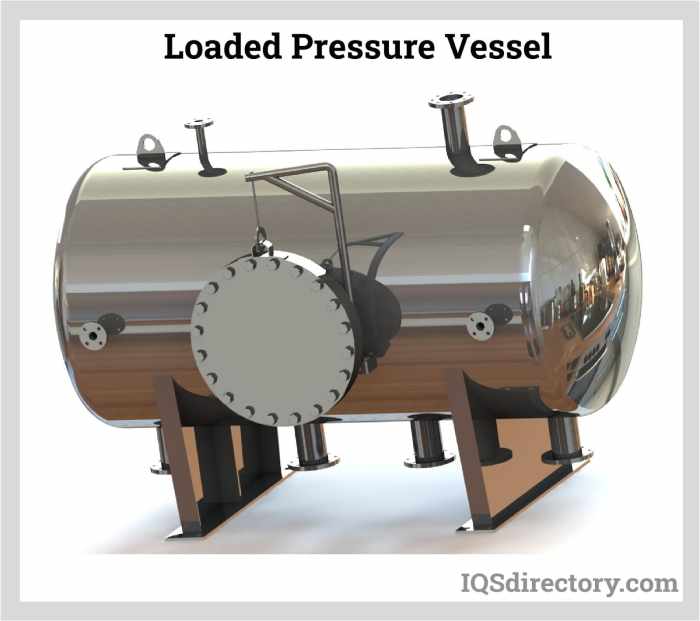

- Cylindrical Pressure Vessels:These are the most common type of pressure vessels, featuring a cylindrical shape with dished or flat ends. They are commonly used for storing and transporting gases, liquids, and slurries.

- Spherical Pressure Vessels:Spherical pressure vessels offer the highest strength-to-weight ratio compared to other shapes. They are primarily used for storing high-pressure gases and liquids, such as in scuba tanks and submarine hulls.

- Horizontal Pressure Vessels:Horizontal pressure vessels are designed with a horizontal orientation, often used for liquid storage and transportation. They provide easy access for maintenance and cleaning.

- Vertical Pressure Vessels:Vertical pressure vessels are positioned upright and are suitable for storing liquids or gases that require vertical orientation for optimal performance, such as in distillation columns or gas separators.

- Autoclaves:Autoclaves are specialized pressure vessels designed to withstand high temperatures and pressures. They are commonly used for sterilization processes in laboratories, healthcare facilities, and food processing plants.

Design Considerations

The design of pressure vessels involves careful consideration of several factors to ensure safety and functionality:

- Material Selection:The material used for the pressure vessel must be compatible with the intended contents and withstand the operating pressure and temperature. Common materials include steel, stainless steel, aluminum, and composites.

- Wall Thickness:The wall thickness of the pressure vessel is determined based on the internal pressure, material properties, and safety factors. It must be sufficient to prevent vessel failure under the specified operating conditions.

- Shape Optimization:The shape of the pressure vessel is optimized to minimize stress concentrations and ensure uniform load distribution. Cylindrical and spherical shapes are commonly used due to their inherent strength and ease of fabrication.

- Safety Standards and Regulations:Pressure vessels must comply with relevant safety standards and regulations, such as ASME Boiler and Pressure Vessel Code (BPVC) and European Pressure Equipment Directive (PED), to ensure safe operation.

Manufacturing Processes

Pressure vessels are manufactured using various processes to achieve the desired shape, strength, and integrity:

- Welding:Welding is a primary method for joining metal components of the pressure vessel. Different welding techniques, such as arc welding, gas welding, and laser welding, are employed depending on the material and application.

- Forming:Pressure vessels can be formed using techniques like rolling, forging, or spinning. These processes shape the metal into the desired geometry and thickness.

- Heat Treatments:Heat treatments, such as annealing, tempering, and quenching, are applied to improve the material properties, reduce residual stresses, and enhance the overall strength and durability of the pressure vessel.

Applications of Pressure Vessels

Pressure vessels are widely used across various industries:

- Chemical Processing:Pressure vessels are used in chemical plants for reactions, storage, and transportation of chemicals, gases, and liquids under pressure.

- Power Generation:In power plants, pressure vessels are employed in boilers, turbines, and heat exchangers to contain high-pressure steam or gases.

- Aerospace:Pressure vessels are essential components in aircraft and spacecraft, used for fuel storage, oxygen supply, and hydraulic systems.

- Food and Beverage Industry:Pressure vessels are utilized in food and beverage processing for sterilization, pasteurization, and packaging.

- Medical and Pharmaceutical Industry:Autoclaves and other pressure vessels are used in medical facilities and pharmaceutical plants for sterilization and drug manufacturing.

Inspection and Maintenance

Regular inspection and maintenance are crucial for ensuring the safety and longevity of pressure vessels:

- Visual Inspection:Visual inspections involve examining the pressure vessel’s exterior and interior for signs of corrosion, cracks, or any other damage.

- Non-Destructive Testing (NDT):NDT techniques, such as ultrasonic testing, radiography, and magnetic particle testing, are used to detect hidden flaws and defects within the pressure vessel.

- Pressure Testing:Pressure testing involves applying a controlled internal pressure to the vessel to verify its integrity and ensure it can withstand the intended operating pressure.

- Maintenance Procedures:Regular maintenance procedures, such as cleaning, lubrication, and replacement of components, help extend the lifespan of the pressure vessel and prevent failures.

Essential FAQs

What is the primary function of a pressure vessel?

Pressure vessels are designed to contain fluids under pressure, enabling their safe storage and utilization in various applications.

What are the key design considerations for pressure vessels?

Pressure vessel design involves careful selection of materials, optimization of wall thickness, and adherence to safety standards to ensure structural integrity and prevent catastrophic failures.

How are pressure vessels manufactured?

Pressure vessels are typically fabricated using welding, forming, and heat treatment processes, with specific techniques employed based on the vessel’s intended application and operating conditions.