Industrial motor control 7th edition pdf – Delving into the realm of industrial motor control, the 7th edition PDF emerges as an authoritative guide, meticulously crafted to illuminate the intricacies of modern motor control systems. This comprehensive resource empowers readers with a profound understanding of the principles, components, and applications that govern the efficient operation of industrial motors.

Through a lucid exposition of fundamental concepts and practical applications, this 7th edition PDF establishes itself as an indispensable tool for engineers, technicians, and students alike. Its in-depth coverage of advanced topics, including programmable logic controllers and distributed control systems, equips readers with the knowledge necessary to navigate the complexities of industrial motor control in the 21st century.

1. Industrial Motor Control Overview: Industrial Motor Control 7th Edition Pdf

Industrial motor control plays a pivotal role in modern industries, enabling efficient and precise operation of various machines and systems. It involves the regulation of electric motors, which are the workhorses of industrial processes, to achieve desired performance characteristics.

Types of Industrial Motors and Applications

- AC Motors: Induction motors, synchronous motors, and brushless DC motors are commonly used in industrial applications, offering high efficiency, reliability, and durability.

- DC Motors: Brushed and brushless DC motors provide high torque at low speeds and are suitable for applications requiring precise speed and torque control.

- Stepper Motors: These motors offer precise positioning and are ideal for applications like CNC machines and robotics.

- Servo Motors: Servo motors combine high torque, precise speed control, and rapid response, making them suitable for demanding applications such as robotics and motion control systems.

Brief History of Industrial Motor Control

The roots of industrial motor control can be traced back to the late 19th century with the advent of electric motors. Early control methods involved manual switches and rheostats. Over the years, advancements in electronics and control theory have led to the development of sophisticated control systems, including programmable logic controllers (PLCs) and distributed control systems (DCSs).

2. Motor Control Principles

Motor control principles encompass the fundamental concepts and techniques used to regulate the operation of electric motors. These principles form the foundation for designing and implementing effective motor control systems.

Open-Loop and Closed-Loop Systems

Motor control systems can be classified into two main types: open-loop and closed-loop systems.

- Open-Loop Systems: In open-loop systems, the control signal is generated based on a predetermined reference value without considering the actual output. They are simpler to implement but offer limited accuracy and performance.

- Closed-Loop Systems: Closed-loop systems use feedback to monitor the actual output and adjust the control signal accordingly. This feedback mechanism provides improved accuracy and performance, making them suitable for demanding applications.

Control Techniques

- PID Control: Proportional-Integral-Derivative (PID) control is a widely used control technique that adjusts the control signal based on the error between the desired and actual output.

- Vector Control: Vector control is an advanced control technique that uses mathematical transformations to represent the motor’s magnetic field vectors. It provides precise control over both torque and speed, resulting in improved efficiency and performance.

Sensors and Feedback Devices

Sensors and feedback devices play a crucial role in closed-loop motor control systems. They provide information about the motor’s actual output, such as speed, torque, and position. Common sensors used in motor control include encoders, tachometers, and current sensors.

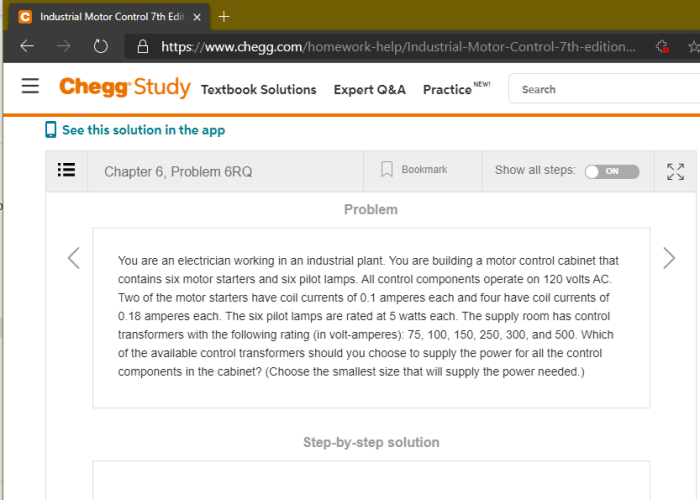

3. Industrial Motor Control Components

Industrial motor control systems comprise various components that work together to regulate the operation of electric motors. Understanding the functions and characteristics of these components is essential for effective motor control system design.

Contactors, Industrial motor control 7th edition pdf

Contactors are electromechanical switches that connect or disconnect power to the motor. They are used for starting, stopping, and reversing the direction of the motor.

Relays

Relays are smaller electromechanical switches that are used to control the operation of contactors and other devices. They are typically used for logic functions and interlocks.

Drives

Drives, also known as variable frequency drives (VFDs), are electronic devices that control the speed and torque of AC motors. They offer precise control and energy savings compared to traditional methods.

4. Motor Control Applications

Industrial motor control finds applications in a wide range of industries, from manufacturing and transportation to energy and automation. Understanding the specific requirements and challenges of each application is crucial for designing effective motor control systems.

Manufacturing

- Machine tools: Motor control is essential for precise positioning and speed control of machine tools, such as CNC machines and robots.

- Conveyor systems: Motor control ensures smooth and efficient operation of conveyor systems, handling materials and products throughout manufacturing facilities.

Transportation

- Electric vehicles: Motor control plays a vital role in electric vehicles, regulating the speed and torque of the electric motor.

- Escalators and elevators: Motor control ensures safe and reliable operation of escalators and elevators, transporting people and goods.

Energy

- Wind turbines: Motor control is used to regulate the speed and torque of wind turbines, optimizing energy generation.

- Power plants: Motor control is essential for the operation of pumps, fans, and other equipment in power plants.

5. Advanced Topics in Industrial Motor Control

Advanced topics in industrial motor control encompass sophisticated control techniques and systems that enhance the performance and capabilities of motor control systems.

Programmable Logic Controllers (PLCs)

PLCs are programmable controllers that are used to implement complex logic and control functions in industrial motor control systems. They offer flexibility, reliability, and ease of programming.

Distributed Control Systems (DCSs)

DCSs are distributed control systems that provide centralized monitoring and control of multiple motor control systems. They enable remote access, data logging, and advanced control strategies.

6. Troubleshooting and Maintenance

Troubleshooting and maintenance are critical aspects of industrial motor control systems to ensure optimal performance and longevity. A systematic approach to troubleshooting can help identify and resolve issues quickly and efficiently.

Troubleshooting Common Motor Control Problems

- Motor not starting: Check power supply, contactor operation, and motor connections.

- Motor running too fast or too slow: Verify speed control settings, drive parameters, and sensor feedback.

- Motor overheating: Inspect for mechanical issues, excessive load, or cooling system problems.

Preventive Maintenance Strategies

- Regular inspection: Inspect motor, drive, and other components for wear, damage, or loose connections.

- Condition monitoring: Monitor motor temperature, vibration, and other parameters to detect potential problems early.

- Scheduled maintenance: Perform scheduled maintenance tasks, such as cleaning, lubrication, and component replacement, to prevent failures.

Key Questions Answered

What are the key benefits of using the industrial motor control 7th edition PDF?

The industrial motor control 7th edition PDF offers a comprehensive and up-to-date overview of the field, providing readers with a thorough understanding of the principles, components, and applications of industrial motor control systems.

Who is the target audience for the industrial motor control 7th edition PDF?

The industrial motor control 7th edition PDF is an invaluable resource for engineers, technicians, and students seeking to expand their knowledge of industrial motor control systems. Its accessible writing style and in-depth coverage make it suitable for both beginners and experienced professionals.

What are the advantages of using advanced control systems in industrial motor control?

Advanced control systems, such as programmable logic controllers (PLCs) and distributed control systems (DCSs), offer increased precision, efficiency, and flexibility in industrial motor control applications. They enable real-time monitoring, data logging, and remote control, leading to improved system performance and reduced maintenance costs.